Description

PRODUCT DESCRIPTION & FEATURES

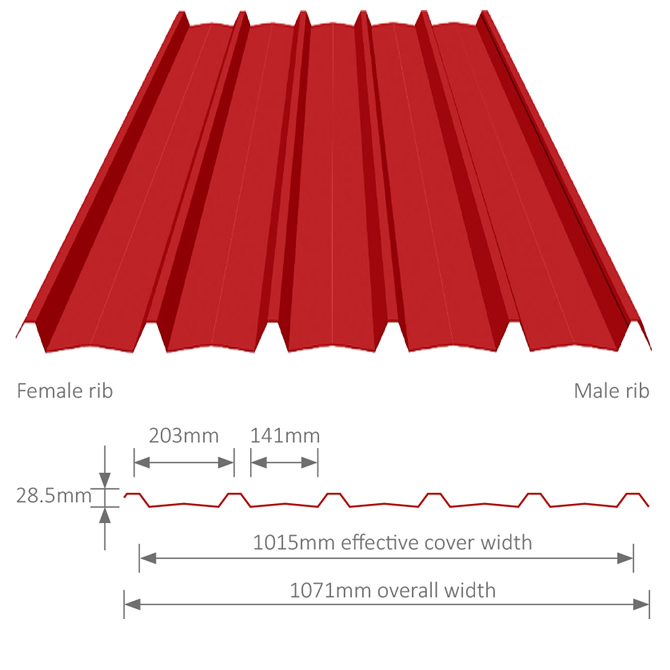

Trimflute IBR roof sheeting is a subtle square-fluted profile. The long flute gives the profile its strength with long-spanning capabilities. Trimflute IBR fix can be used as a roofing as well as a cladding profile. The square flutes of Trimflute IBR type sheeting ensure excellent drainage characteristics. The contemporary appearance of Trimflute IBR roof sheeting is aesthetically appealing. Trimflute IBR profile can be factory-cranked, curved and bull-nosed to a wide range of radios. For further details contact our Technical Department.

The Trimflute IBR profile is roll-formed with 6 trapezoidal ribs at 203 mm, centres with a net cover of 1015 mm. The rib height shall be 26.5 mm and shall be fixed per the manufacturer’s recommendations.

Sample Specifications

The sheeting shall be Trimflute IBR type profile as manufactured by Safintra Roofing. The Trimflute IBR profile shall be roll-formed with 6 trapezoidal ribs at 203 mm, centres with a net cover of 1015 mm. The rib height shall be 26.5 mm and shall be fixed in accordance with the manufacturer’s recommendations. Safintra 0.50 mm thick, ZincAl® AZ 150 Trimflute Profile Roof Sheeting, fixed to internal steel purlins at 1600 mm centres and to ridge and eaves purlins at 1400 centres, with Fixtite® or Safintra approved 12 x 65mm long Hex Head self-drilling screws at every second crest, internal purlins and every crest. Eaves purlins side laps to be stitched at 500 mm centres between purlins all in accordance with manufacturer recommendations

Fastening

Trimflute IBR is pierce-fixed to timber or steel supports. This means that fastener screws pass through the sheeting. You can place screws for Trimflute IBR through the crests or in the valleys. To maximise water tightness, always place roof screws through the crest. For walling, you may use either crest or valley fixing. Always drive the screws perpendicular to the sheeting and in the centre of the corrugation or rib. Don’t place fasteners less than 25 mm from the ends of sheets.

The edge of the Trimflute IBR with the anti-capillary groove is always the under-lap. It is generally considered good practice to use fasteners along side-laps however, when cladding is supported as indicated in purling spacings, side-lap fasteners are not usually needed for strength.

End-laps are not usually necessary because Trimflute is available in long lengths. If you want end laps, seek advice from your nearest Safintra office on the sequence of laying and the amount of overlap. When Trimflute is laid on slopes of 7.5 degrees or more, cut back the corner of the undersheet, at the downhill end of the sheet to block capillary action.

Lengths & Roof Pitch

When using Trimflute IBR roof sheeting the recommended minimum pitch for roof slopes in excess of 15m is 10° and for slopes less than 15m is 7,5°. Trimflute IBR roof sheeting can be ordered in any length, subject to transport limitations, up to 13,2m. Longer lengths require special transport arrangements.

Reviews

There are no reviews yet.