Description

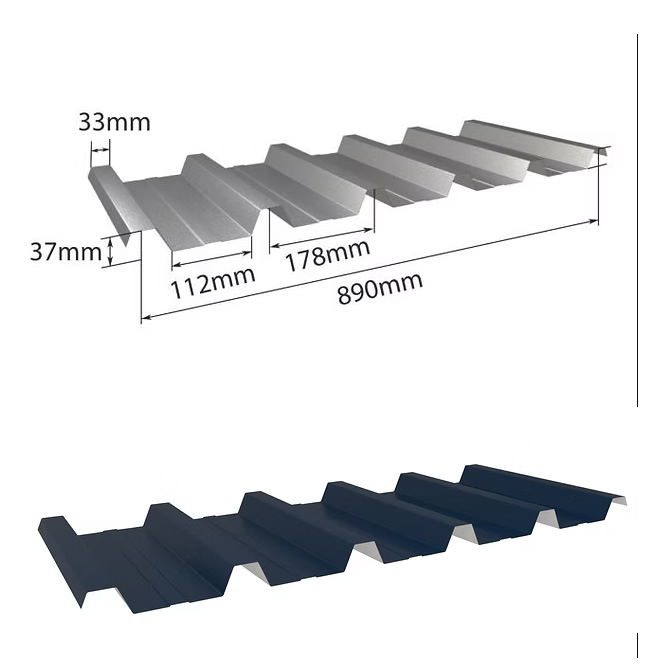

The IBR 890 (Supa-Clad) profile, manufactured by Global Roofing Solutions, is a versatile and durable roofing and cladding solution. Its trapezoidal rib design provides exceptional strength, mass, and load-span capabilities, making it a preferred choice for a wide range of applications.

Key Features of IBR 890 (Supa-Clad) Roof Sheeting

- Profile Design: Six trapezoidal ribs at 178mm centers, providing a net cover of 890mm. Each pan incorporates one stiffener rib for added strength.

- Rib Height: 37mm, ensuring structural stability and resistance to weathering.

- Material Options: Available in various materials, including aluminum, galvanized steel, Zincalume, and COLORBOND, to suit different project requirements.

- Installation: Fixed using screws through the narrow flute for roofing or broad flutes outward for side cladding.

Applications

- Roofing: Ideal for residential, commercial, and industrial roofing projects.

- Cladding: Suitable for wall cladding in warehouses, factories, and agricultural buildings.

Technical Specifications

- Roof Pitch: Minimum pitch of 5° for rafter lengths up to 30m; 7.5° for lengths exceeding 30m.

- Cranking: Can be cranked from a minimum radius of 450mm for material thicknesses of 0.47mm, 0.5mm, 0.53mm, 0.58mm, and 0.8mm.

- Curving: Can be curved to any radius greater than 800mm, subject to transportation limits.

- Sheet Length: Available in lengths up to 12.5m (standard) or 18.6m (with special transport arrangements).

Installation and Handling

- Assembly: Sheets must be laid in strict accordance with the manufacturer’s specifications.

- Site Handling: Sheets should be stored under well-ventilated cover, clear of the ground, and protected from damage during construction.

- Cleaning: Ensure the roof remains clean and free of swarf and debris during and after installation.

Quality Assurance

- ISO Certification: Manufactured under ISO 9001:2015 Quality Management System standards.

- Fasteners: Compatible fasteners must be selected to match the life expectancy of the roofing material, as per SANS 1273 standards.

Additional Notes

- Flashings: Use purpose-made flashings and polyclosures for sealing and finishing.

- Expansion Joints: Recommended for spans exceeding 24m (crest fixing) or 15m (valley/pan fixing).

Reviews

There are no reviews yet.